Continuous billet heating furnace

Features:

Application: Forging , Forging & Rolling

Material Heated:Carbon Steel & Alloy Steel

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product Name: Continuous billet heating furnace

Typical Application:

It is mainly used for billet heating before forging or rolling, and the billet size can be 75*75, 100*100, 120*120, 130*130, 135*135, 150*150, 165*165, 180*180 or customized. The length is not limited.

Forever focus is to lead the market in top quality heating and continuous billet heating furnace by providing automatic and innovative systems for long-life features.

Advantages

- High heating speed

- Oxidation with less decarburization

- Energy saving, less pollution

- High degree of automation, full automatic operation can be realized

- Heating temperature uniformity, high control precision.

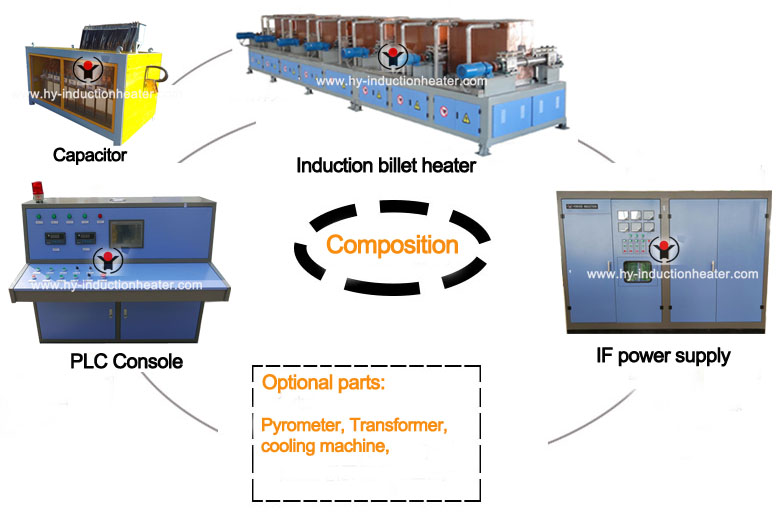

continuous cast billet heating machine configuration

1. Furnace frame (including capacitor, water circuit, electrical circuit, gas circuit)

2.Billet induction heater

3. Storage platform and automatic feeding device with pinch roller

4. Infrared thermometer system

5.Transformer (according to the actual needs of customers)

6.Capacitors (according to the actual needs of customers)

7.PLC operation console

8. Cooling tower

9. induction heating power supply

Mechanical part

The mechanical part is made up of furnace frame, loading mechanism, feeding mechanism, discharging mechanism and so on. Its action setting and heating beat are completed by PLC.

1.Feeding mechanism: Feeding mechanism is completed by the storage platform, the front V groove and the conveying device. The discharge port is equipped with the discharge mechanism of the roller so that the billet will not damage the inlet.

2.The furnace frame is steel welding assembly, which includes water line, electric furnace, capacitor and so on.

3. Infrared thermometer

The temperature measuring device adopts a non-contact infrared thermometer, which is equipped with temperature display and multiple output interfaces for printing or recording instruments. The temperature display on the external control panel has the characteristics of high accuracy, good reliability and anti-environmental impact. When the measuring temperature exceeds the set value, it has sound and alarm function.

| Billet size | Billet length | Heating Temp. | Production capacity |

| 60*60mm2 | 3m-4 m | 1000℃-1100℃ | 25T/H |

| 75*75mm2 | 3-6 m | Room Temp.-1100℃ | 25T/H |

| 100*100mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 120*120mm2 | 750℃-1100℃ | 30T/H | |

| 120*120mm2 | 11.5-12.5m | 950℃-1150℃ | 90T/H |

| 125*125mm2 | 6 m | Room Temp.-1200℃ | 8T/H |

| 125*125mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 130*130mm2 | 6 m | 950℃-1150℃ | 50T/H |

| 135*135mm2 | 6 m | 950℃-1150℃ | 100T/H |

| 150*150mm2 | 11.5-12.5m | 950℃-1150℃ | 70T/H |

As our billet induction heater is all customized, the above parameters are only for your reference.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.